Palletizing Software

Main Features:

• User-friendly graphical run-time user interface.

• Easy graphical pallet patterns for creation and editing.

• Complete palletising application setup for single or multiple lines.

• System integrator uses tools with PC and/or edits robot programs for specific applications providing tailored performance and maximum flexibility.

• Maximizes palletising performance from robot.

• Integrated alarms handling.

• Option to collect and display data.

• Optional control of multiple robots from one PC.

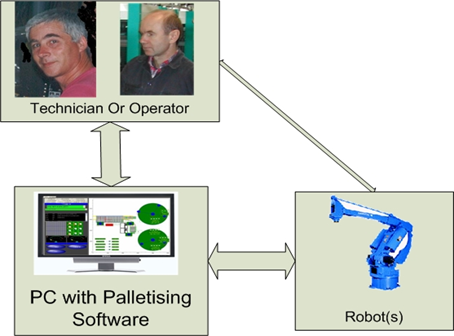

A choice of configurations is available to suit varying levels of operational complexity:

For Installation & Operation

PC software used by technician for setup

& by operator for day-to-day use

Just for Installation

PC software used only for setup

after which PC may be disconnected

Robot will carry on palletising:

In either case the system may include a PLC to control conveyors.

The system may:

1) Control single or multiple lines.

2) Include a PLC to control conveyors

Main Screen – Example 1

3 Palletising Lines:

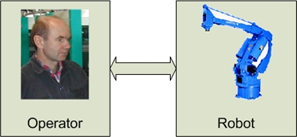

Main Screen – Example 2

5 Palletising Lines – 2 Robots:

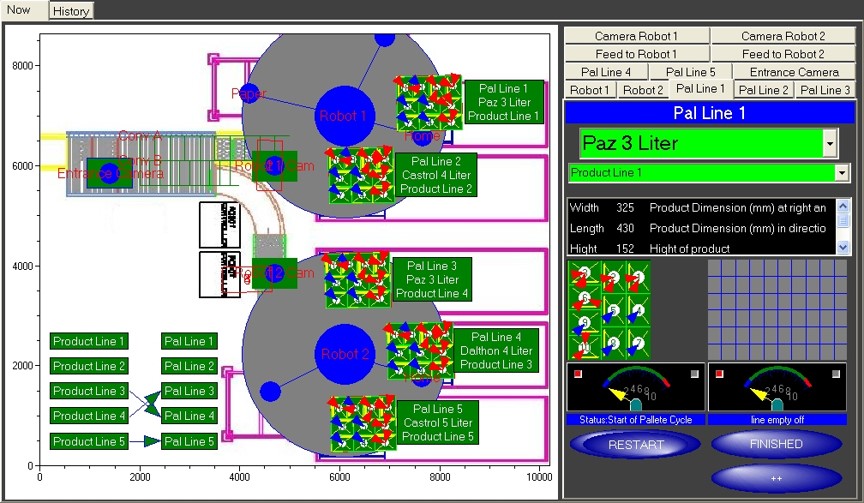

Main Screen – Example 3

1 Palletising Line:

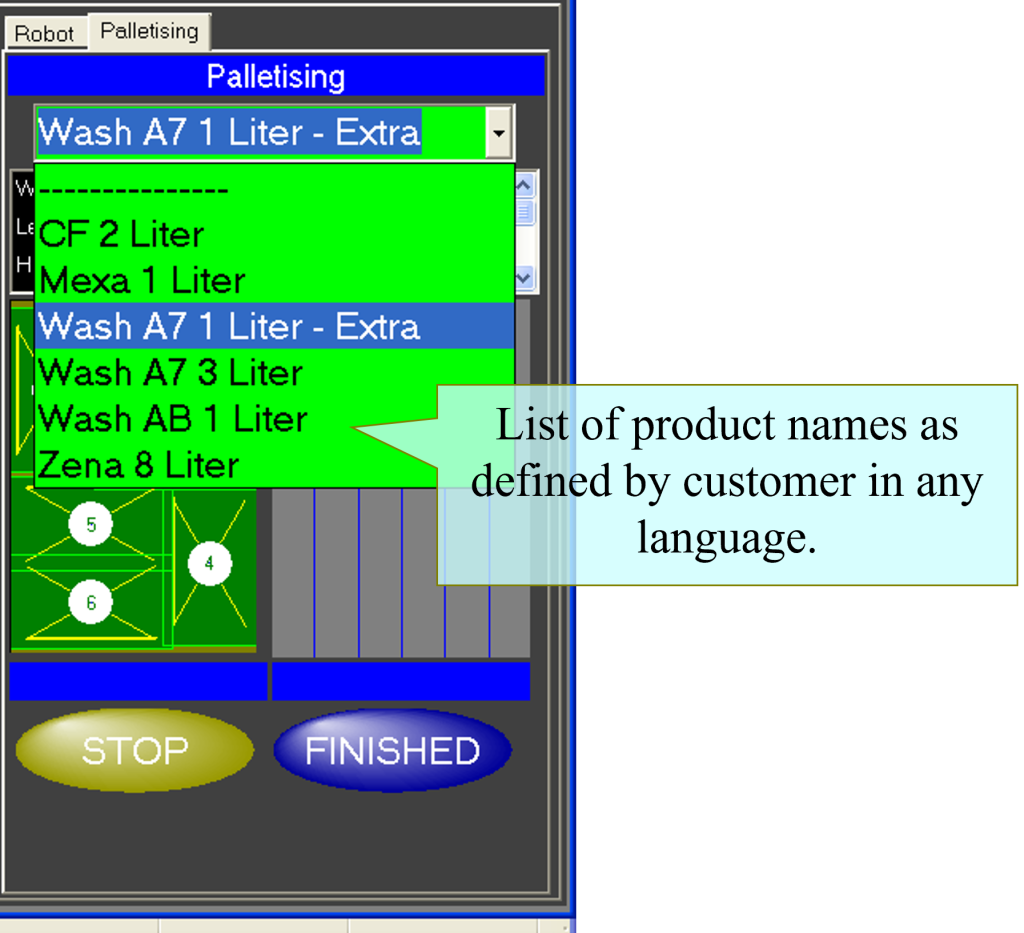

Easy Product Selection:

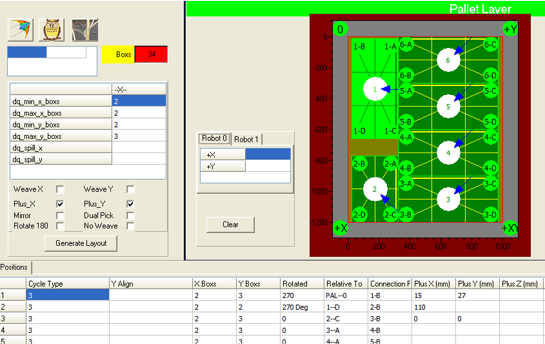

Straightforward Pallet Setup

• Set up all details of Pallet Layout via Setup Screens.

• Place units of product one after another as required.

• Support for pick and place of varying quantities of product.

• Software can automatically suggest layout based on product parameters.

• User-specified robot path for each placement.

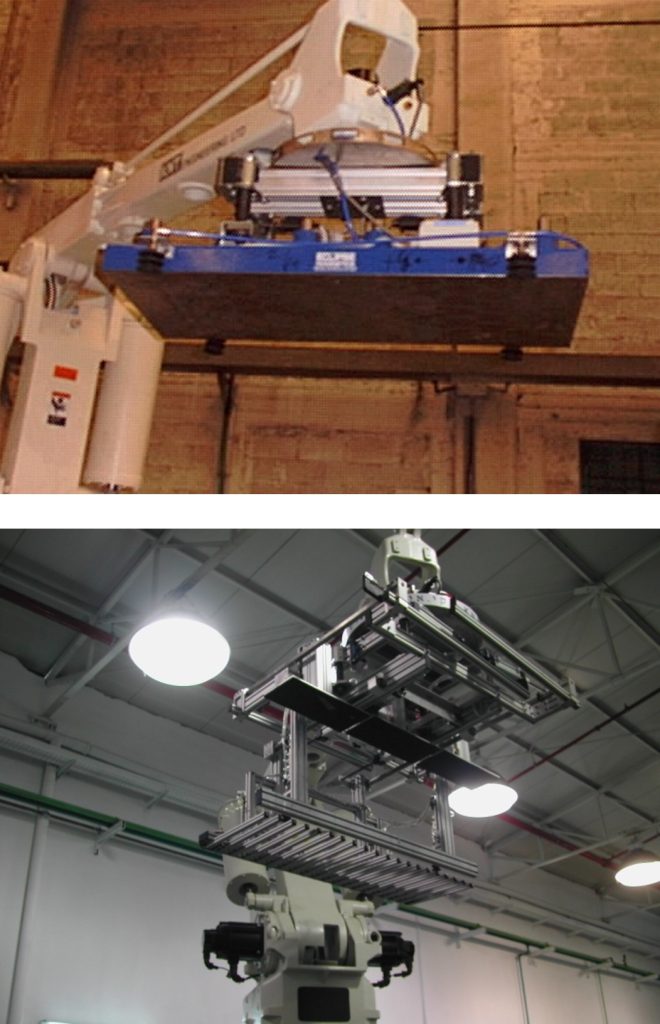

Grippers

Can be adapted for use with a variety of gripper types including:

•Vacuum gripper

•Magnetic gripper

•Mechanical gripper

•Fork-type gripper

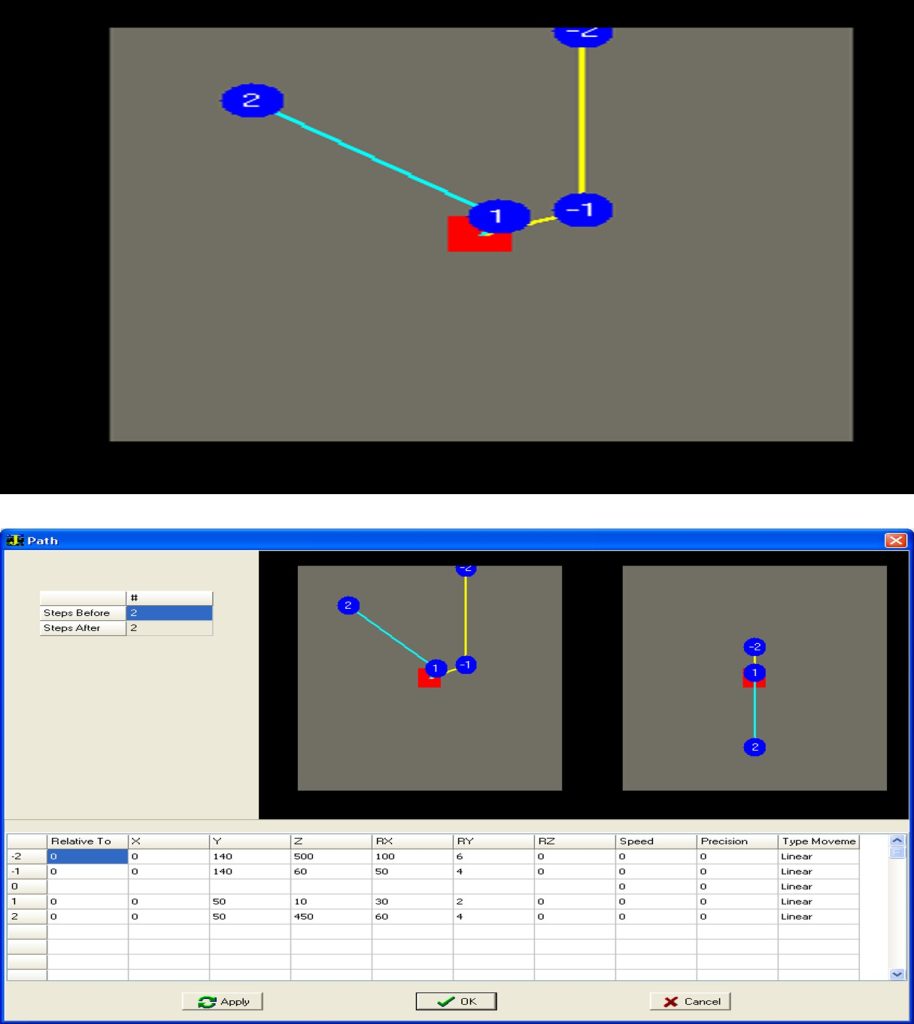

Setup Of Paths

•User sets up path to pick and place positions.

•Setup can be easily adjusted at any time.

Robot Locations

•Most locations are stored on PC along with setup user data and time of setup.

•Setting up multiple pallet patterns requires no further location instruction.

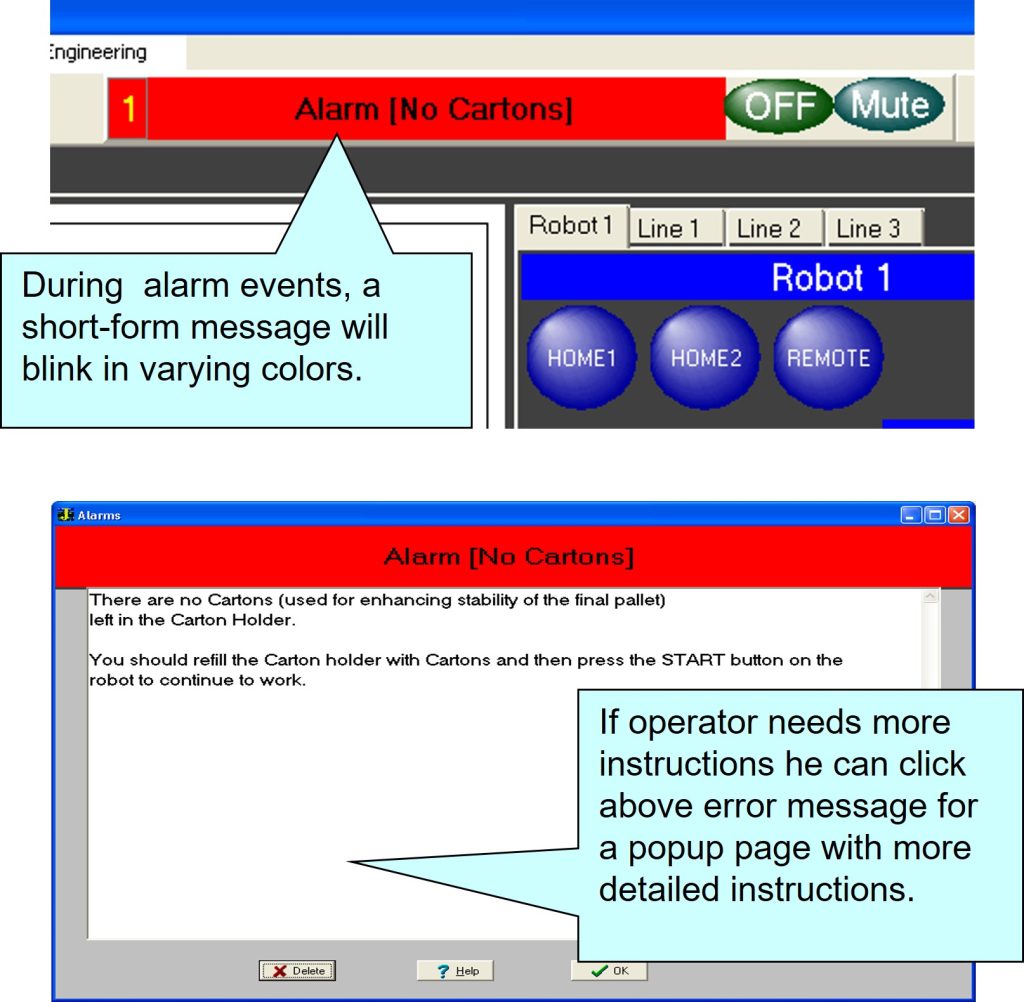

Alarms

•Alarm events trigger popup on-screen messages.

•Alarm list can be modified by installer or system manager.

•Users may customize alarm events messages on-site.

•Alarm log stored according to preset times.

•Alarm log available for display at any time.

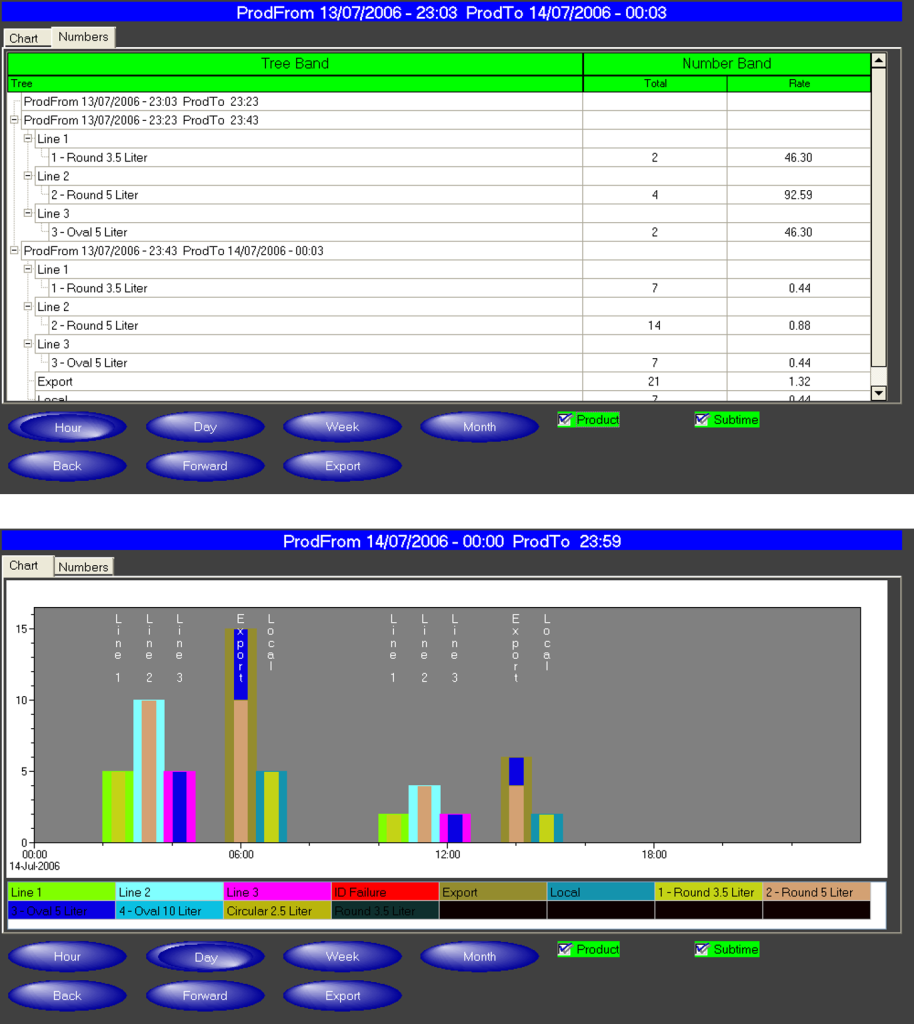

Data Collection And Reports

•Option to collect data on palletised quantities from various lines.

•Reports for various time periods.

•Data display in numeric or graphic format. Possibility of data export to readable Excel format

Software Design – Summary:

The Pallet Cell Controller Software is designed to more easily facilitate the setup and running of a robotic palletising application.

Setup

The many details of the palletising application setup are contained in a user-friendly interface: number and locations of palletising lines, tools, frames, conveyors and pattern arrangements of products on the pallet base.

The user may begin with data from a previous installation, amending details as needed.

PC Requirements:

PC with: RS232 Com port

Motoman Plug for Motocom32 software

Options:

• Advantech Digital IO board or USB module (necessary only in the event of statistics collection or for alarms display on PC).

Example Application

Motoman SP-100 At NirLat Company

•3 incoming/outgoing lines, palletising buckets of paint.

•20 different pallet patterns.

Example Application

Motoman 20 kg Robot At Paz Company

•1 line arranging bottles of liquid product in cartons.

•7 different pallet patterns.

Example Application

Motoman SP-100 At Sano Company

•3 incoming/outgoing lines, palletising boxes containing bottles of household cleaning liquids.

•30 different pallet patterns.